Welcome to DFS Engineering Sdn Bhd

DFS is System integration company that very committed to our customer by providing factory Robotic as well as Engineering Automation Solutions that will move forward into Industry 4.0 together through collaborative solution.

DFS consists of more than 15 years experienced industry automation team of application engineers & strong relationship with expertise of speciality vendor from different field in the manufacturing industry that well understood customer needs and requirement.

Key Services Offered :

- Turn Key Project – Robotic Automation System

( Arc Welding, Deburring , Grinding, Vision QC and Pick & Place Palletizing - Arc / Spot Welding Jig and Welding Automation system

- Dedicated Assembly System

- Poka-yoke/ VIsion Inspection Assembly Station

- All kind of Checking Fixture and Inspection jigs

- Customized Automation& Consultation

- Engineering spare part fabrication,

Laser Cutting, Bending, CNC Milling, CNC Turning and Customized parts.

2018

Established

058

Project Done

Authorized Robot Dealer

Product & Solution offered

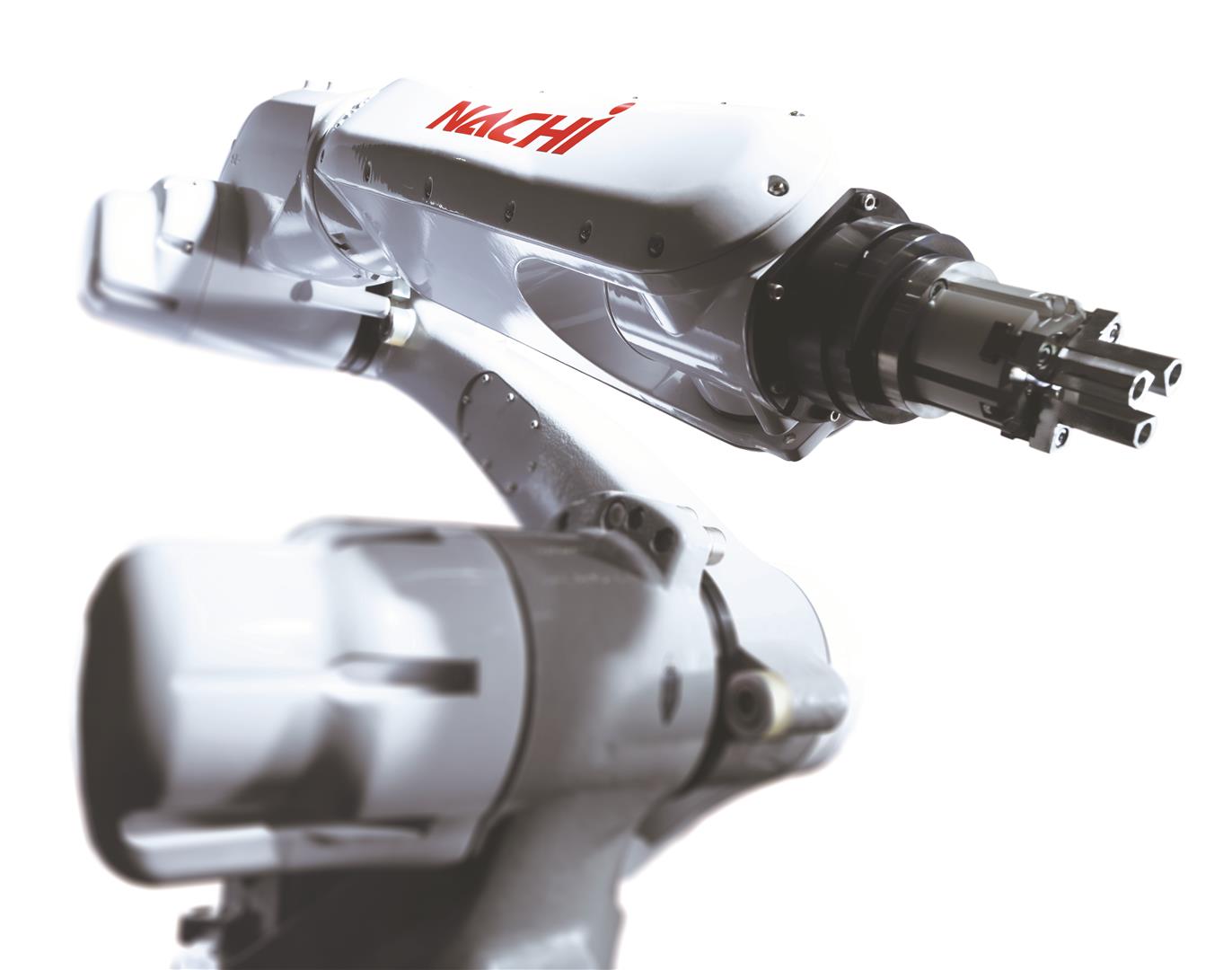

Industrial 6-Axis Robot

Nachi Robotic Systems is a leader in the production of Robotics with payload capacities from 1kg to 1000kg. .

Collaborative Robot

TM Robot is a high-performance & production tool that is highly compatible & flexible to man and machine collaboration

Robotic Turn Key Solution

Turn-Key Solution from Robotic Deburring, Grinding, Arc Welding Cell, Vision Inpection, Pick & Place…

Dedicated & Customization Automation

Tailored made design & build industrial automation machine base on DFS development flow

Jigs & Fixtures

Checking Fixtures, Inpection Jigs, Welding Jigs, Assembly Jigs and others…..

Engineering Parts Supply

Design, Drawing, Fabrication in CNC Machining, Bending, Cutting, Welding, Treatment and Finishing

Our Project Development Flow & Services Provided

Customer Site Surveying

Site surveying to fully undertand the current production process is very important task to be carry out before any of automation/ robotic implementation proposal.

Discussion & Brainstorming

Interview user and brainstorming gave us better understanding the real problem and direction of implementation.

Design & Concept Proposal

Proposal of tailored made design solution is our responsibility to our customer .

Fabrication & Assembly

Maintaining fabrication quality and efficient assembly are no one better than we knows from the initial design stage.

Installation & Integration

Well trained Robotic engineer and integration engineer allow us provide stand one step in front to others be your ony system integrator .

Delivery & Improvement

On time delivery is our priority comitmemnt to our user and never say stop to continuous improvement activities .

Question & Answer

Do our factory need automation or robotic system?

Of course you need! Either industrial automation or robotic system is an essential equipment that every manufacturing customer/owner needed in order to make themselves to be more competitive in global market.

Can Robotic/Automation help us to improve quality as well as increase production volume ?

Robotic system or automation system is design to work with minimum human interference and its work constantly production schedule.

How is collaborative robot benefit to production althought is high investment ??

Collaborative robot is current high acceleration market trend in industrial robotic automation due to its cna work closely with robot bring the complicated job speed up to maximum efficient .

What can DFS offer to customer?

DFS is very focused in system integration in manufacturing industry that provide all kind of solutions from industrial automation to fully robotic cell system to provide solution to customer in term of improved product quality and at the same time keep the production efficiency to maximum

Project Reference

Deburring Robot Station

Manual Operator Deburring Process has been years trouble to all Die Casting customer. By implementing DFS Robotic Deburring Cell, customer now can reduce manpower by 50% and increased output dramatically. The main reason behind is robot deburring cell has consistent output volume , consistent quality finishing and fast deployment. Please contact us by tailored made Robot deburring system……

Robot system, robot automation, arc welding , arc welding jig, jig and fixture, welding robot, welding automation, welding jig, welding structure, automation welding, machine automation, robot, pick and place robot , robot system, fully auto robot system, robot welding cell, checking jig, inspection jig, custom machine, assembly machine, pick and place robot, deburring robot, handling robot, handling automation, inspection robot, process automation, manufacturing automation, efficiency automation.